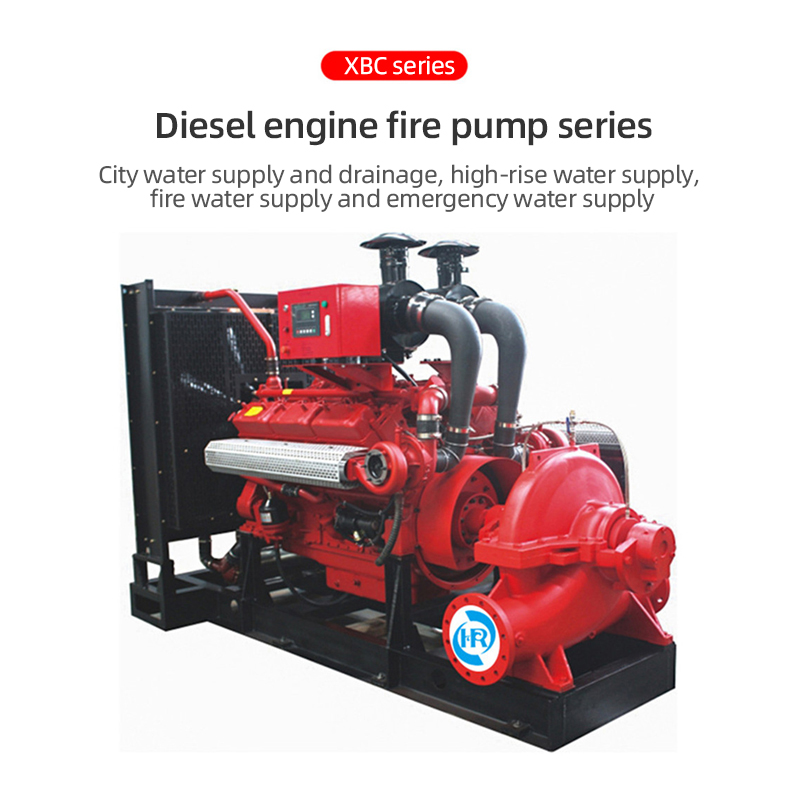

product brief the fire pump set driven by diesel engine shall be designed and manufactured in accordance with gb fire pump. meet the latest cccf certification requirements. the product has the advantages that when a fire occurs, the power supply fails, and the electric fire pump group cannot be put into use normally, the diesel engine fire pump group can be put into operation automatically to ensure the normal fire fighting. compared with the electric fire pump group, it has two advantages: no need for long-term investment in power supply, saving the municipal power supply transformer and normal expenses. the diesel engine fire pump set is equipped with various automatic functions to meet the customer's use requirements, to ensure the long-term normal standby state of the equipment, and to put the fire fighting work at any time.

the diesel engine fire pump set is also suitable for various emergency standby pump occasions.diesel engine drive

model meaning

xbc series electric and diesel fire pump set

as a kind of fixed fire-fighting equipment, the xbc-w full-automatic diesel engine fire-fighting pump set of hairui zhonglian has been widely used in fire-fighting shunt, especially in the case of no power supply or abnormal power supply (mains power), etc. the fire pump equipped in the unit is horizontal single-stage and multi-stage special fire pump. it is mainly composed of diesel engine, fire pump, coupling device, oil tank, radiator, battery, intelligent full-automatic control panel, etc.

the intelligent diesel engine water pump products developed by our factory take the unattended intelligent system as the standard configuration. the product has the characteristics of mature technology, high degree of automation, excellent performance, complete protection functions, reasonable structure, simple installation and high cost performance. at the same time, in order to meet the different needs of users and reasonable investment, the products are divided into fire pump, industrial emergency water pump, agricultural water pump, marine water pump, trailer flow water pump station and other application series, which can be used in linkage with the electric fire pump.

supporting water pump: single pole fire pump, multi-stage fire pump, single pole middle opening double suction fire pump.

working conditions:

1. altitude of sea level: ≤ 2500m

2. ambient temperature: - 25 ~ 55 ℃

3. relative humidity of air: 9-95%

4. seismic intensity: 7 degrees

5. flow range: 50-700 (l / s)

6. lift range: 32-600m

7. diesel engine power: 18-1100kw

8. material of flow passage parts: cast iron, nodular cast iron, stainless steel, cast copper.

9. diesel engine brands: shangchai, dongfeng, cummins, deutz, fiat iveco, wuxi power, weichai, etc.

scope of application:

1. the purpose of various fire hydrants and sprinkler main pumps.

2. it is suitable for all kinds of fire booster and pressure stabilizing pump occasions.

3. various villas, communities and other fire protection systems.

4. fire water system of industrial and civil buildings.

5. it is suitable for various oil depots, oil loading and unloading terminals, logistics parks and other occasions with high fire protection requirements.

scope of work:

1. water supply pressure: 0.2mpa-2.5mpa (20-250m)

2. flow range: 5-1200l / s

3. power: 3kw-2000kw

4. speed range: 1500-3200r / min

5. allowed media: drinking water, chilled water, fire water and other media without abradable impurities or long fiber impurities, and without chemical or mechanical corrosion to the water pump.

6. the maximum allowable medium temperature is 70 ℃, and the maximum ambient temperature is 40 ℃

7. the maximum allowable working pressure is 1.6mpa, and the maximum inlet pressure is 0.6mpa.

main features of diesel pump set:

1. automatic operation: when the diesel engine fire pump unit receives the effective fire signal and remote control start signal, the unit will start automatically. when the power supply system of the motor fire pump unit is cut off to form the signal of phase loss, the unit will be in special state automatically. if the diesel engine fire pump set starts for 10s and fails to start, it will stop for 10s and then restart. the unit will automatically repeat three times;

2. automatic charging: the unit will be charged automatically when the battery voltage is low when the battery is in standby mode at the automatic position. when the battery voltage is sufficient, the charging can be stopped automatically to avoid damage to the battery;

3. automatic alarm: multiple start failure alarms, diesel engine low oil pressure alarm, diesel engine water temperature alarm, diesel engine ultra-high speed alarm and shutdown, battery low voltage alarm, charging failure alarm, fuel lack indication alarm, etc.

4. automatic preheating: keep the diesel engine in hot standby state to ensure emergency work;

5. direct connection: the diesel water pump unit below 360kw adopts the technology of direct connection of diesel engine and water pump through elastic coupling, which is the first in china. it reduces the failure point, greatly shortens the starting time of the unit, and increases the reliability and emergency performance of the unit;

6. users can also request to set other alarm output (non-standard supply);

7. it has telemetry, remote signaling and remote control functions (non-standard supply);

8. wide range of type spectrum: single stage single suction pump, multi-stage single suction pump, single stage double suction pump, etc. can be selected for the fire pump set. or a variety of pump combinations in parallel, wide range of flow, pressure.

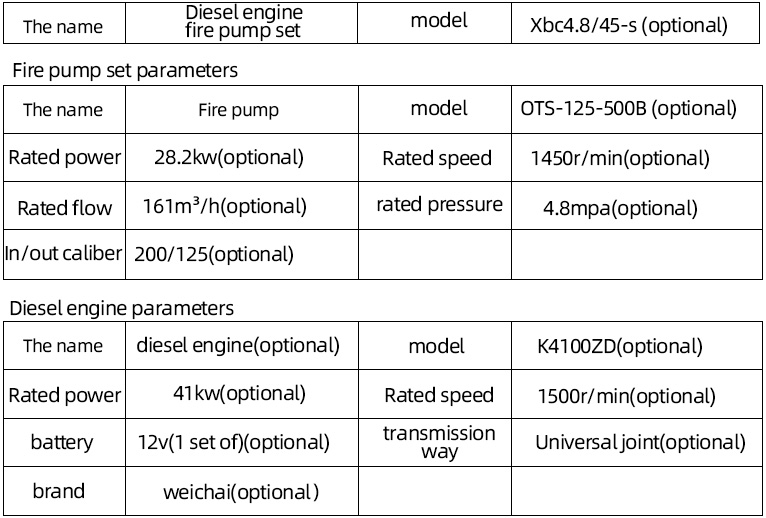

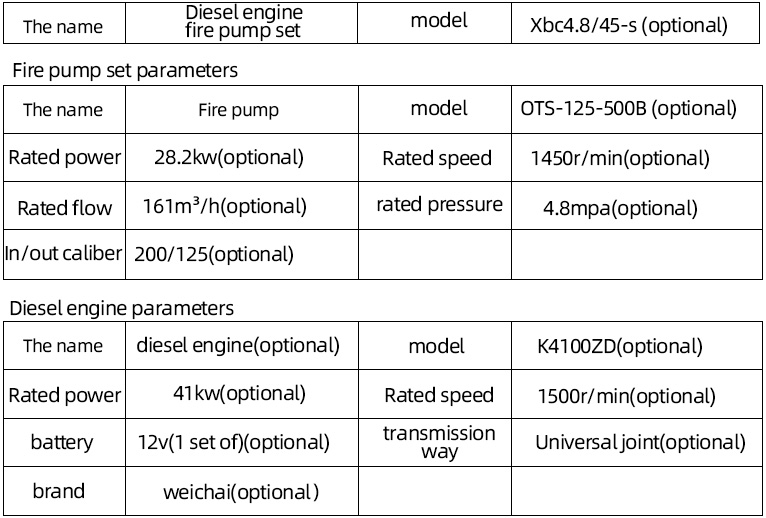

pump unit equipment parameters

the following parameters are only for reference of products requiring other model parameters or other supporting equipment. please contact us to help you select the model. if it is beyond the scope, it can be customized.

performance parameter

diesel engine selection

diesel engine

1. single cylinder or double cylinder diesel engine shall be used for power less than 20kw;

2. q385 is used for power 20kw-30kw.

3. power: 30kw-56kw four cylinder diesel engine 4100, 4102, 4108, etc.

4. power: 70kw-300kw six cylinder diesel engine 6105, 6113, 6135.

5. power 300kw-2000kw8, 12, 16 cylinder diesel 12v135azd, kt38, etc.

how to select type

1. the rated power of the selected diesel engine shall be greater than 10% of the maximum shaft power of the water pump. under abnormal conditions, the power of the diesel engine will not reach the rated power. in order to ensure normal operation, it is necessary to select a high-power diesel engine and water pump. note the rated power of diesel engine is measured under the following standard conditions;

2. the ambient atmospheric pressure is 100kpa.

3. ambient temperature 25 ℃.

4. air relative humidity 30%.

5. when the altitude of the working place is increased by 100m, the power will be reduced by 3%.

fuel tank selection

tank capacity

the fuel tank capacity is generally 190-250g / kw. h per hour under rated power load. calculate the 6-hour fuel consumption, leaving 10-15% margin.

capacity of oil storage tank

the capacity of the main fuel oil storage tank (tank) is calculated based on the expected rated fuel consumption and operating time. in the design of fuel tank capacity, the minimum fuel supply for continuous operation shall be taken as the standard;

tank installation

1. it is recommended that the user install an oil-water separator on the oil supply pipeline;

2. when connecting the pipeline of the oil tank, it is strictly prohibited to use ordinary raw material to bring sealing, so as to prevent the pipeline from entering the diesel engine due to dissolution, resulting in pipeline blocking;

3. the installation position of oil tank shall avoid heat source and vibration, because vibration will cause sediment to rise, while heating will cause power drop;

4. considering the fire protection requirements, it is recommended to place the oil tank above 1000l separately and isolate it from the diesel engine fire pump set;

5. fuel temperature is an important factor that affects the good operation of diesel engine. the oil temperature higher than 60 ℃ will lead to volume expansion, obviously reduce the heat capacity per unit volume of fuel oil, reduce the output power of diesel engine, and avoid the influence of external heat source on the oil temperature;

6. it is suggested that the installation position of the oil tank should be such that the maximum suction head is not more than 2m, and the suction head of the output pump should be calculated from the bottom of the oil tank;

7. the oil tank shall be kept away from the sun. the oil tank shall be placed away from the fire source. smoking is not allowed near the oil tank. sparks or flames are not allowed. volatile fuel will cause explosion. and there should be corresponding fire fighting facilities (such as foam extinguisher, sand, etc.) near the fuel tank. strictly prohibit the use of water as a fire fighting material. it is recommended that the fire tank department should get the approval of the fire department when placing the fuel tank larger than 2000l.

the following is the selection function, which is proposed when ordering:

1. the speed can be adjusted. when the flow and head of the water pump are inconsistent with the actual requirements, the speed of the diesel engine can be adjusted to meet the actual situation.

2. battery circuits, one for use and one for standby.

3 maintenance free battery, no need to add replenishing fluid for maintenance.

4 preheat to ensure normal startup at low temperature.

5 regular patrol inspection can be set to ensure the normal operation of the unit.

6. data remote transmission, which can realize the function of data remote transmission. the operation of the device can be seen in real time by using app on the mobile phone.

7.the protection level of 7 houses is increased to ip44.

8 different brands of diesel engines.